Mission

Vision

Strategy

A challenge? Yes it is, but we will meet this challenge!

About VelWa

Steel preservation is a complex process. VelWa has extensive experience in inspecting blasted steel surfaces and paint systems. VelWa is able to provide sound advice related to surface preparation and paint systems, drawing on highly relevant professional experience of Cees Wassenaar. VelWa believes in collaboration among people with a shared passion for steel preservation. Clear agreements, concise reports, relevant and feasible recommendations ensure enhanced cooperation and a optimum quality of paint preservation systems.

In addition to the fact that Cees was director of a preservation company for years, he has gained a lot of experience in the field of conservation in large projects. Below you will find a number of them.

Until January 1, 2023, VelWa has always been led by Ton van Velzen and Cees. Ton no longer works at VelWa. He enjoys a wonderful retirement.

Cees is NACE 3 certified Coating Inspector (no. 66049)

THOR Project

Project: Jacket en platform

Client: HSM Offshore Energy

Preservation: several coating systems related to the corrosion class CX

Assignment:

– Checking the submitted quality plans of the various coating companies.

– Assurance of the quality of the preservation by means of specific quality plans and reporting at HSM

– Execution of the inspections at several subcontractors, including reporting tot HSM

Period: January 2024 – present

ONE Dyas

Project: Jacket en platform

Client: HSM Offshore Energy

Preservation: several coating systems related to the corrosion class CX

Assignment:

– Checking the submitted quality plans of the various coating companies.

– Assurance of the quality of the preservation by means of specific quality plans and reporting at HSM

– Execution of the inspections at several subcontractors, including reporting tot HSM

Period: April 2023 – present

Windplan Blauw

Project: 24 fundations in the IJsselmeer (near the Ketelbridge) for windmills

Client: Ballast Nedam Renewables – Nieuwegein

Preservation: C5 – 3 layers coating system

Assignment:

– Checking the submitted quality plans of the various coating companies.

– Assurance of the quality of the preservation by means of specific quality plans and reporting

– Execution of the inspections at the start of the conservation work at the various coating companies, and then specifically on handrails and Davit cranes.

Period: July 2022 – April 2023

New Zaanbridge

Project: New bridge over the river Zaan

Client: HSM Steel Structures – Schiedam

Preservation: C5 – 3 layers coating system

The province of North Holland has commissioned HSM Steel Structures

to produce the New Zaanbrug.

VelWa has been asked to monitor the conservation process and to report the findings.

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: November 2022 – April l2023

Petrogas > 2 Small Gas Platforms Petrogas

Project: Monopiles + gas platforms

Client: HSM Offshore B.V. – Schiedam

Preservation: CX offshore Coating system

Location: HSm Offshore Energy – Schiedam

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: May 2022 – April 2023

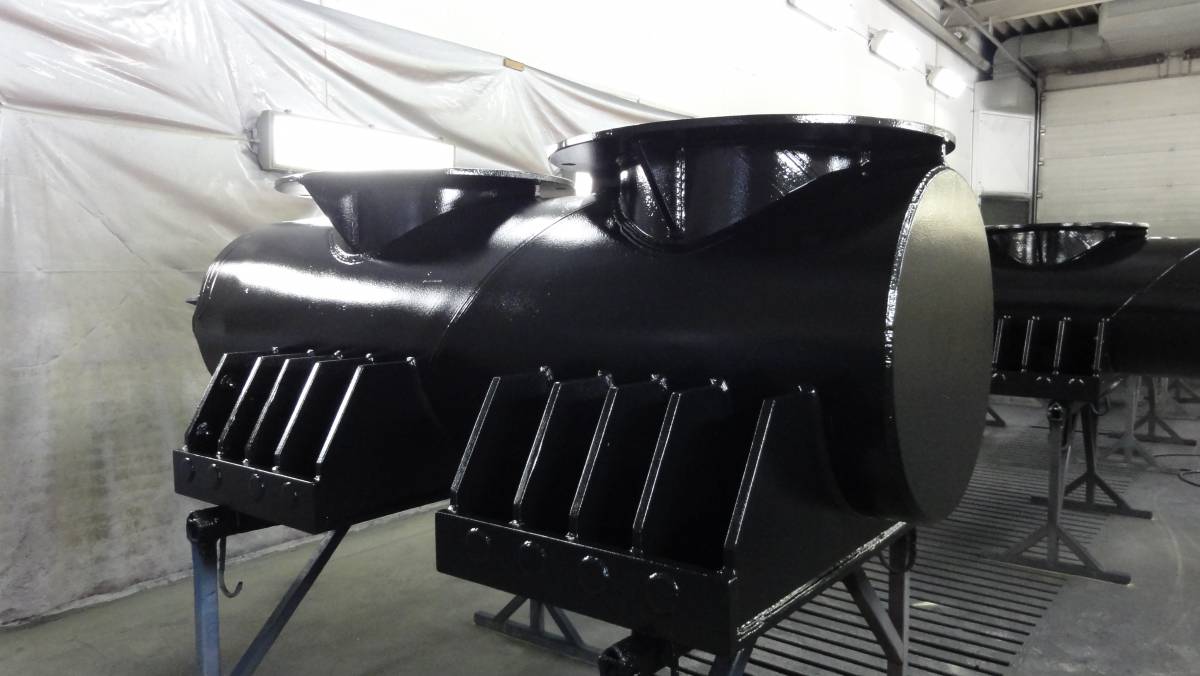

LevveL > Flood barrier Kornwerderzand / Afsluitdijk

Project: Flood barrier

Client: HSM Steel Structures B.V. – Schiedam

Preservation: several coating systems

Location: HSM Offshore – Schiedam

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections in the paint shop.

Period of time: August 2021 – March 2023

Windfarm maasvlakte 2

Project: Monopiles + platforms for windfarm

Client: Ballast Nedam – Nieuwegein

Preservation: several coating systems

Location: Sif Group Netherlands – Maasvlakte Rotterdam

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: March 2022 – May 2022

Motor vessel Visarend

Project: Rijksrederij Rijkswaterstaat – re-preservation of the ship

Client: Damen Shipyards – Den Helder / commisionned by CLOCSS Projects

Preservation: several coating systems

Location: Damen shipyards – location Oudeschild (Texel)

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: November 2021 – December 2021

AGRO Merchants – Dublin

Project: new construction food processing warehouse facility

Client: B-Built – Bergen op Zoom

Preservation: several coating systems

Location: several preservation companies

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: October 2021 – December 2021

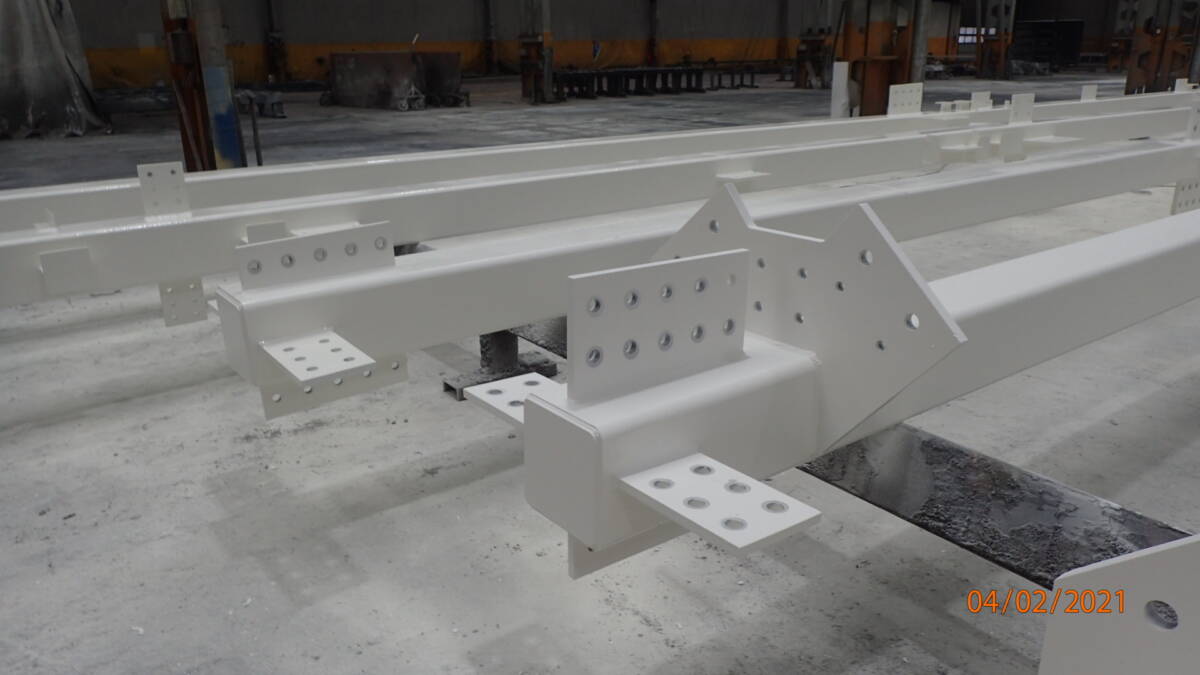

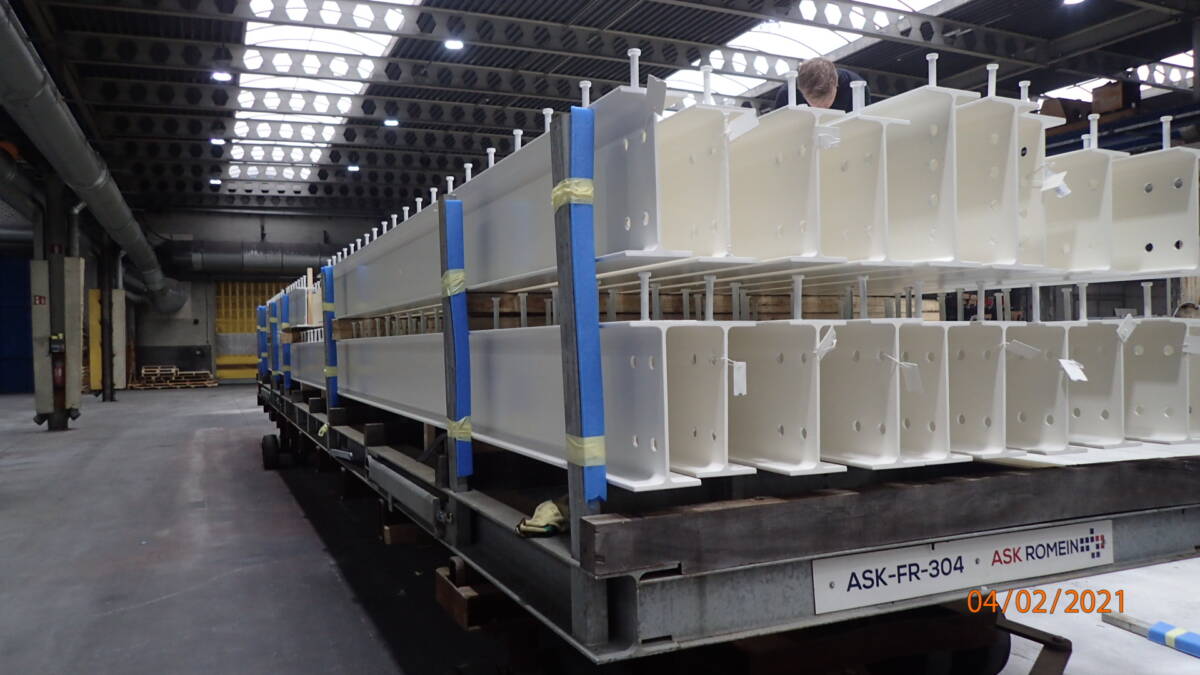

Borealis Antwerp

Project: New plant for Borealis in Antwerp

Client: ASK Romein Staalbouw – Roosendaal

Preservation: 3 different coating systems

Location: Various preservation companies in The Netherlands and Belgium

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: September 2020 – December 2021

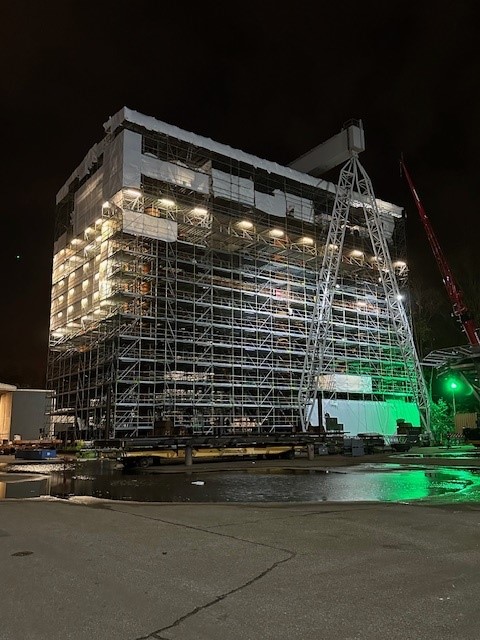

Data Center ODN3 / Odense – Denmark

Project: New data center ODN3

Client: ASK Romein Staalbouw – Roosendaal

Preservation: 3-layer coating system, including intumescent coating

Location: Various preservation companies

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

Period of time: January 2021 – May 2021

AFAS Football Stadium – Alkmaar

Project: New grandstand roof of the stadium

Client: ASK Oostingh Staalbouw – Katwijk

Location: Various preservation companies

The assignment:

– Guaranteeing the quality of the preservation by means of specific quality plans and reporting.

– Conducting the inspections at all preservation companies.

– Guidance / inspections on the construction site in the implementation of the preservation.

Period of time: June 2020 – July 2021

Unilever Building Rotterdam

Project: Repair fire-resistant coating of steel construction on the outside

Client: MVGM Brug & Kade – Rotterdam

Location: Unilever Building Rotterdam

The assignment:

– Prepare for the repair of the steel structure paintwork (2018 – 2019)

– Advising MVGM to choose a painting company for performing the work

– Guidance / on-site inspections in the implementation of the conservation.

Period: May 2020 – August 2020

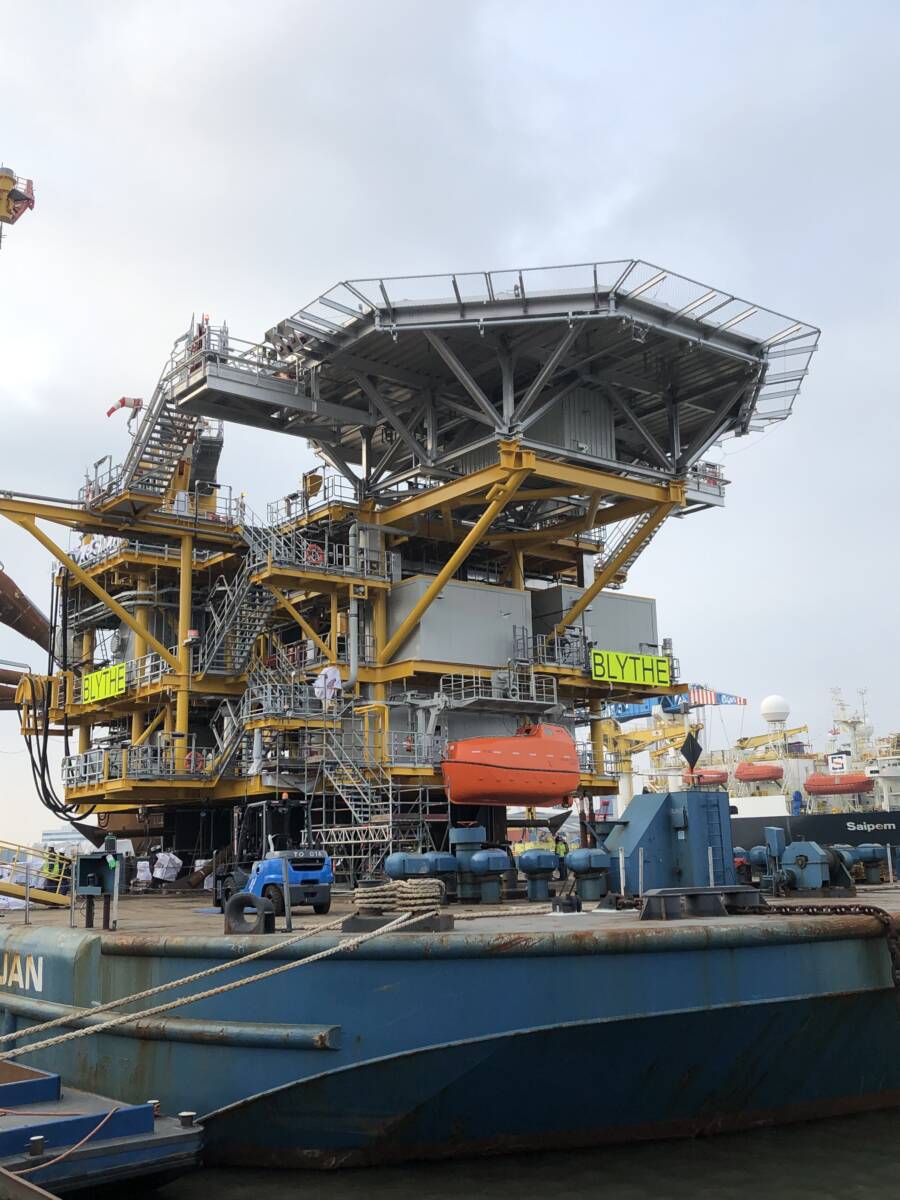

Several projects HSM Offshore

Project: Dana – NNG – IOG

Client: Several

Location: HSM Offshore – Schiedam

Task: to perform inspections of blasting en painting all parts of the constructions

Period of time: March 2020 – June 2021

VelWa advice

Another aspect of VelWa is advising companies (steel construction, contractors, engineering firms) to apply correct conservation (read steel protection) for new projects to be built, but also to advise on repairing a conservation. These recommendations are of a very limited nature. For example, for repairing the preservation, research is first conducted into the reason for, for example, the failure of the preservation. This can vary from incorrect pre-treatment, incorrect paint system, to advice for conservation before renovation. Below a number of examples from 2019:

– Repair of fire-resistant coating preservation at parking garage and office building

– Advice on preservation for renovation of the awning of an office building

– Advice on the conservation of a number of bridges in a park

– Use of fire-resistant coating in a hotel

– Investigation into the status of conservation on a steel structure of a hall, in connection with possible takeover of the building

– Advising associations of owners to come to an amount for service costs for maintenance

Refit Alucia 2

Project: Refit Alucia 2 to oceanXplorer 1

Client: CLOCSS Coating Inspections & Surface Solutions B.V.

Location: DAMEN Shiprepair Rotterdam – Schiedam

Task: to perform inspections of all coating systems on the steel construction, exsisting and new

Period of time: November 2019 – May 2020

Bicycle viaduct Highway A4 Ypenburg to The Hague

Project: Bicycle viaduct between Ypenburg and centre The Hague (335 meters long)

Client: Construction company Hillebrand – Middelburg

Task: Inspection of blasting and coating of all 9 parts of the bridge

Period of time: June 2019 – September 2019

New bridge for Dronrijp

Project: Bridge at Dronrijp, over the Harinxma Canal

Client: Construction company Hillebrand – Middelburg

Task: Supervising the preservation of the bridge an carry out coating inspections

Period of time: Mei 2019 – June 2019

Awning construction Weena in Rotterdam

Project: Awning construction for a building at Weena in Rotterdam

Client: Jones Lang LaSalle – Rotterdam

Task: inspection for blasting and painting of the construction at te conservation company, and final inspectian after assembling

Period of time: April 2019 – May 2019

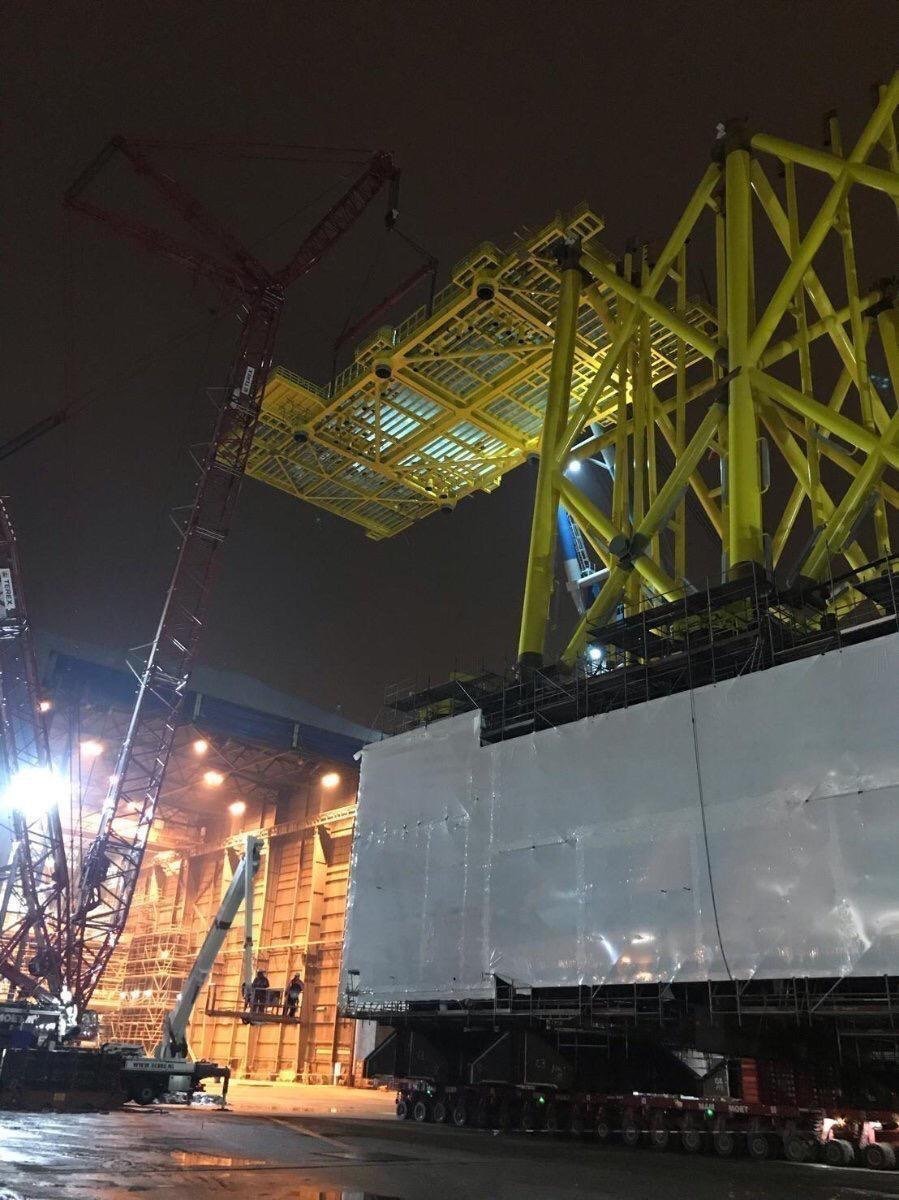

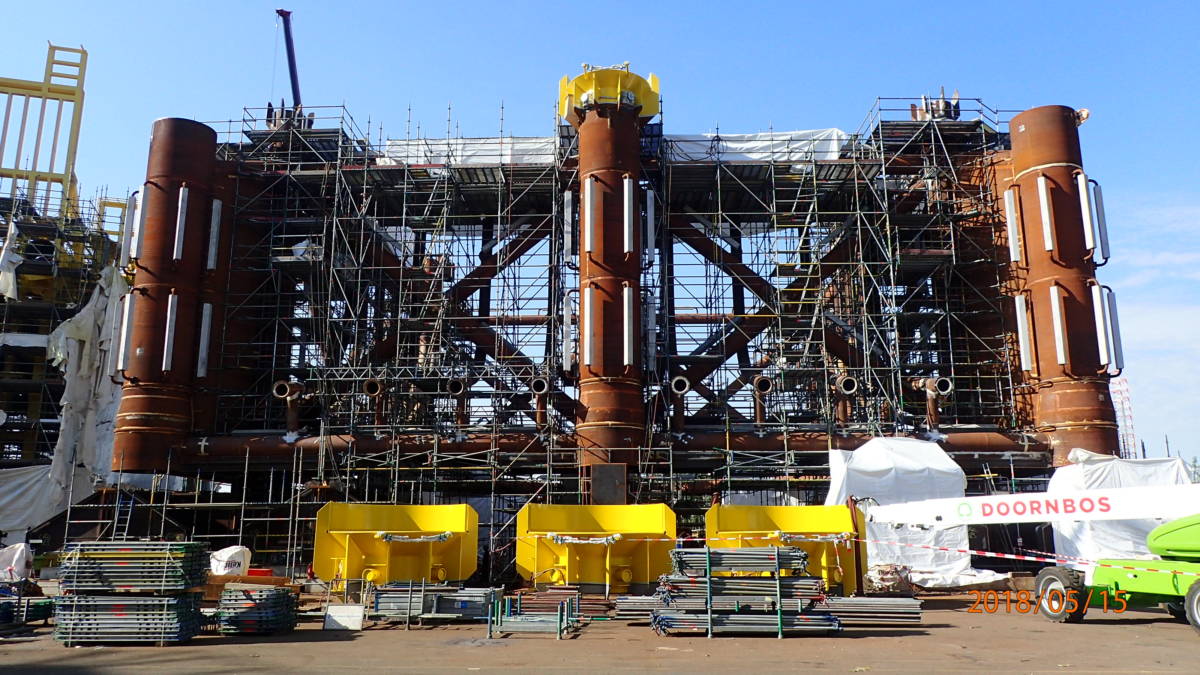

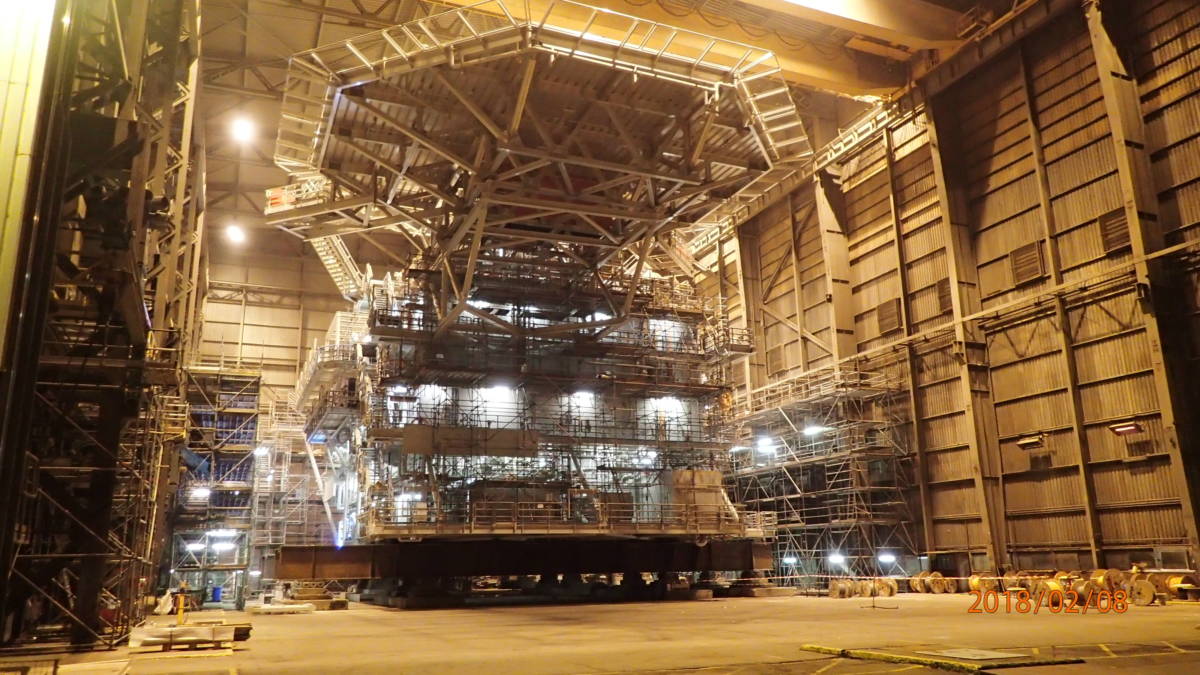

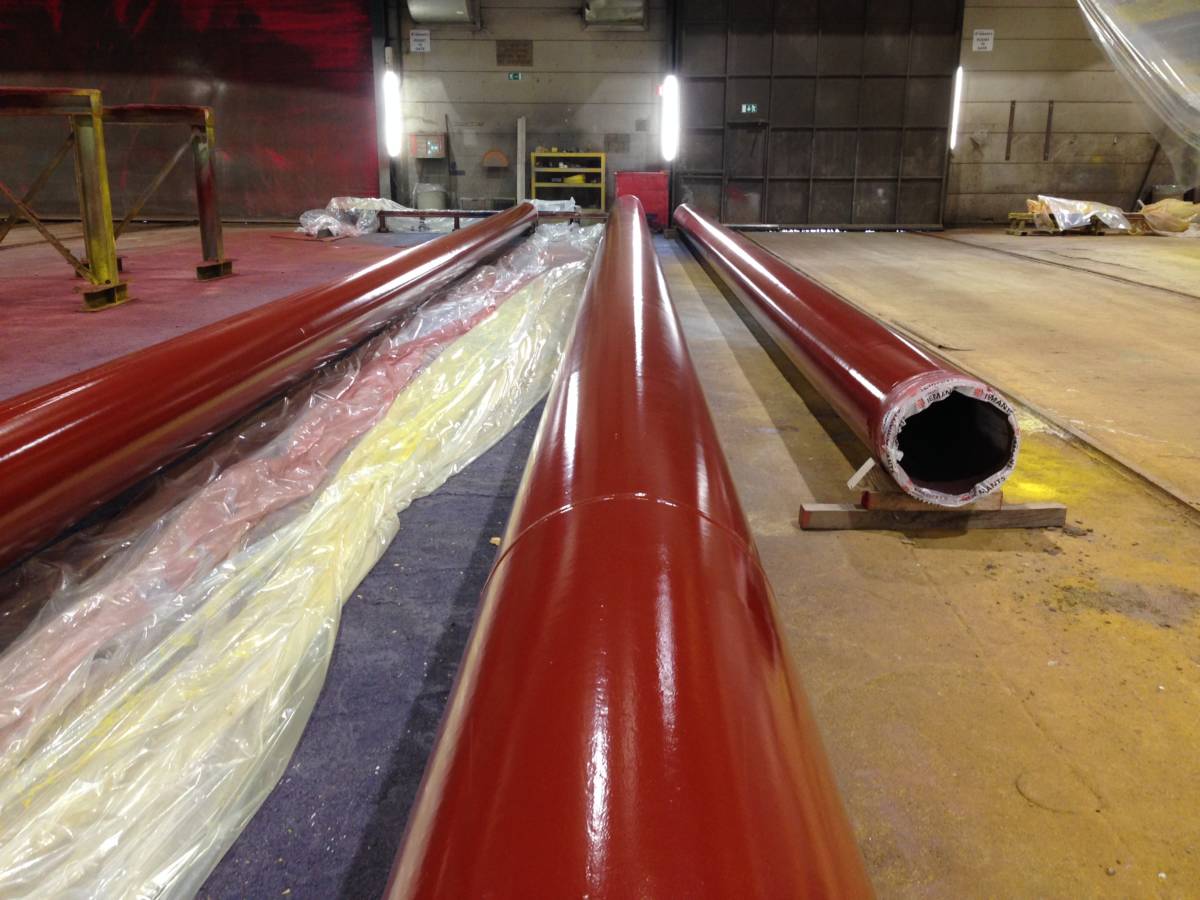

Energy Substation Borssele Beta

Project: Energy Substtion Borssele Beta – TenneT

Client: HSM Offshore – Schiedam

Task: Inspection of blasting and painting of all steel parts for Jacket and topside

Periode: August 2018 – May 2020

Energy Substation Borssele Alpha

Project: Enery Substation Borssele Alpha – TenneT

Client: HSM Offshore – Schiedam

Task: inspection of blasting and painting (including touch up) of all steel parts (Jacket and topside)

Period of time: January 2018 – June 2019

Energy Substation Borkum Riffgrund 2

Project: Topside for Energy Substation Borkun Riffgrund / Dong – Ørsted

Client: HSM Offshore – Schiedam

Task: Inspection of paint repairs and touch up on the topside, before sail away

Period of time: October 2017 – June 2018

Two projects at Iemants – Arendonk (B)

Project: Several staal constructions for offshore purpose

Client: Iemants Steel Structures – Arendonk (Belgium)

Task: Inspections of dry film thickness on every part of the steel construction

Period of time: August 2017 – September 2017

Repair pontoons and walkways

Project: Refit of steel and coating of three pontoons and two walkways for the Dutch Marine – Den Helder

Client: Endures – Den Helder

Task: to carry out inspections on the blasting and painting of the pontoons and walkways.

Period of time: July 2017 – August 2017

Stena Line Europoort (2)

Project: New quay (south side) of Stena Line Europoort – Port of Rotterdam

Client: Ballast Nedam Infra

Task: to perform inspection on the coating system at several conservation companies and at the site itself.

Period of time: May 2017 – December 2017

Chimney Uniper Benelux

Project: Chimney Uniper Benelux enegy station – Maasvlakte Rotterdam

Client: Uniper

Task: to carry out an inspection on the quality of the coating on the outside of the chimney

Period of time: May 2017

Stena Line Europoort (1)

Project: Renewing the qua of Stena Line Europoort in the Port of Rotterdam

Client: Ballast Nedam Infra

Task: To perform inspections of the coating system on the steel constructions at the conservation companies and on site

Period of time: November 2016 – March 2017

Partners

Contact us!

Office:

VelWa Paint Inspection & Consultancy BV

Looyerslaan 20

2223 TG Katwijk

The Netherlands

C. (Cees) Wassenaar : +31 6 53 44 11 30

CC: 73880736

General terms and conditions available on request

Cees Wassenaar

cees@velwa.nl

![]()